Our engineers have extensive skills in the fields of process engineering, process technology and the associated machine and plant technology. We respond to your complex requirements with innovative solutions to achieve the best possible result for you in every respect. Take advantage of our know-how and focus entirely on your business.

Professionally on course Expertise is the key to success

Chemical and thermal process engineering

- Chemical reactor technology

- Recrystallisation and debonding processes

- Extraction of solid and liquid substances

- Distillation of organic solvents

- Fractionation and stripping columns

- Outlet air treatment systems (e.g. absorbers)

- Adsorption systems for outlet air and waste water (e.g. activated carbon adsorption for removing AOX, CHC, DOC etc.)

- Heat transfer processes

- Evaporation processes & drying processes

- Ion exchange processes (decarbonisation, softening, demineralisation, heavy metal removal, iron extraction, demanganisation)

- Oxidation and degassing processes

- Precipitation and flocculation processes

- Sedimentation and flotation processes

Mechanical process engineering

- Bulk material technology

- Storage, feeding and dosage of solid matter (e.g. silos for solid matter, big bag handling, pneumatic feed systems etc.)

- Separation of solid matter and liquids

- Liquid filtration processes (sand and multi-layer filters, bag filters and filter candles)

- Membrane processes (micro, ultra and nano filtration as well as reverse osmosis (RO))

- Screening and grading

- Thickening, decantation

- Stirring, mixing, kneading, dispersing

- Centrifuge processes

- Sedimentation processes

- Milling processes

- Agglomeration and granulation

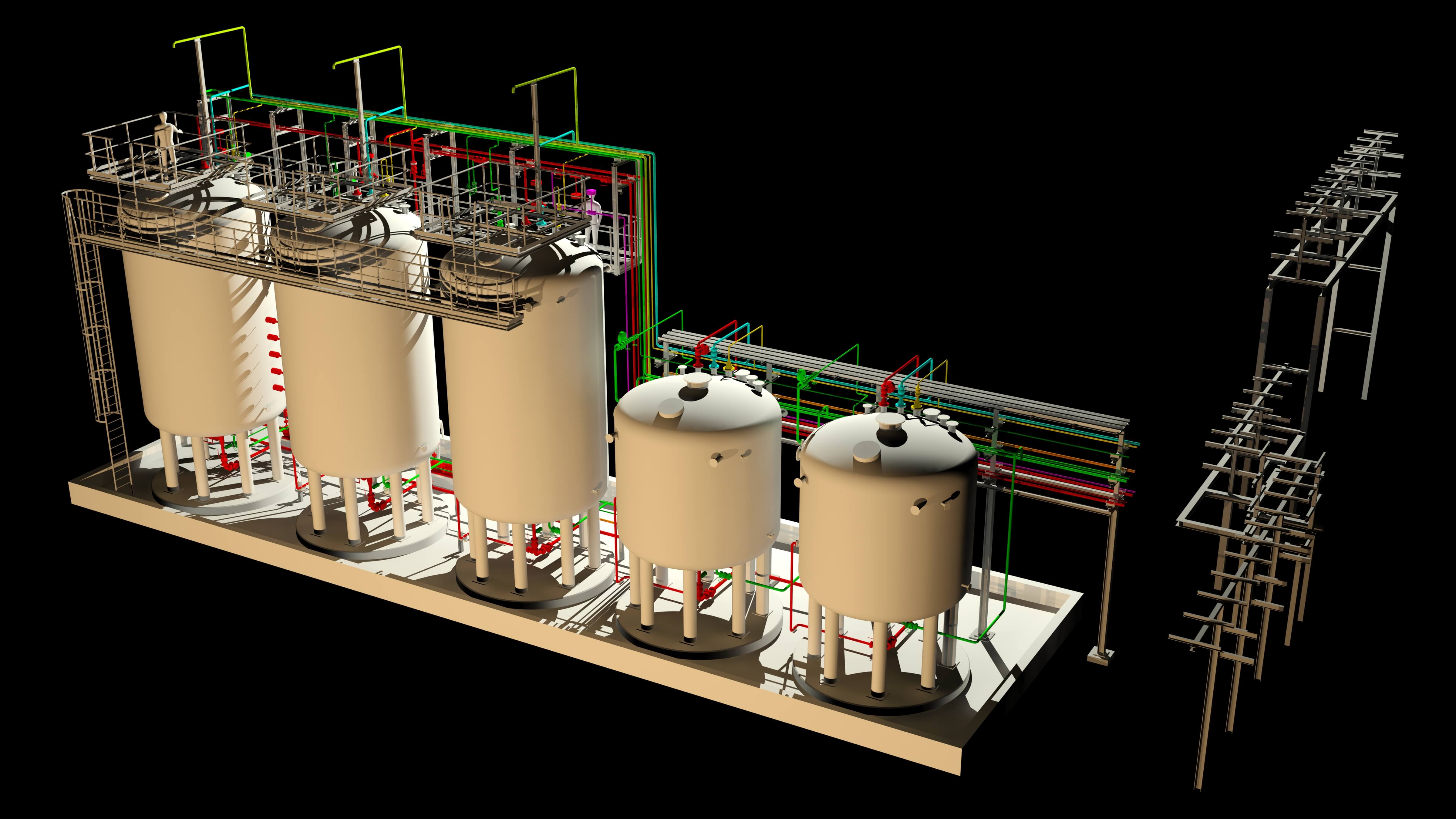

Mechanical engineering and plant construction

- Container construction and silo construction

- Apparatus construction

- Pipeline construction

- Technical insulation

- Line construction/pipe bridge construction

- Pump technology and compressor technology

- Valve technology

- Heat engineering

- Fluid dynamics

- Drives and gears

- Plant planning and costing

- Air conditioning and ventilation construction

- Dosage technology, e.g. for chemicals

- Filling systems and loading facilities (incl. tankers and ships)

- Hygiene technology and sterilisation technology (e.g. CIP and SIP cleaning systems)

Waste water technology and water technology

- Industrial waste water treatment processes, e.g. biological and physiochemical processes

- Industrial and process water treatment

- Drinking water treatment and drinking water supply

- Digested sludge treatment

Supply technology and disposal technology

- Physical steam and condensed water technologies

- Heat transferring oil systems

- Vacuum systems

- Hot and warm water supply

- Cooling water supply/cooling towers

- Refrigeration engineering, ice slurry supply

- Compressed air and nitrogen supply

- Ventilation and air extraction systems

- Above ground and underground storage tanks for substances that are hazardous to water, inflammable or explosive (solvents, food etc.)